-

- Bearing model

-

Model

51272 F

- Internal diameter-(mm)

-

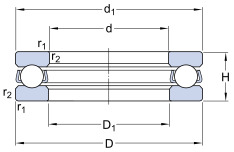

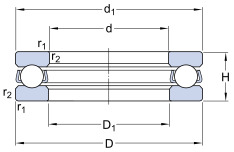

d

360

- External diameter-(mm)

-

D

500

- Thickness-(mm)

-

B

110

- Dynamic load-(kN)

-

cr

741

- Static load-(kN)

-

cor

4150

- Fatigue load-(rpm)

-

Fatigue load

73.5

- Reference speed-(rpm)

-

Reference speed

500

- Limiting speed-(rpm)

-

Limiting speed

700

-

Bearing Type

Thrust ball bearing

There are two key points in the assembly of thrust ball bearing. One is the control of the pressing quality of cage and steel ball, and the other is the control of the nominal height T after the assembly of the bearing. In addition, because the shaft ring and seat ring can be separated, a management problem is to prevent the mixing of imported bearing parts. The bent edge assembly die is used for the M-type pressing cage. After pressing, the steel ball shall rotate flexibly in the pocket, but shall not fall off from the pocket. The technical specification shall check the displacement of the steel ball in the pocket. If the solid cage is pressed too deeply, the steel ball displacement will be small, and the connection between the embossed convex part and the cage is too small and the strength is insufficient, which will easily lead to the falling of the block and cause the cage to be scrapped. The difference between the inner diameter of small thrust ball bearing race and shaft race is very small, and there is no obvious difference between the two sets. In order to prevent the occurrence of mixed sets, that is, two sets of bearings are found to be race or shaft race. This requires taking certain measures. Generally, the ring and seat are distinguished with the aid of auxiliary tooling during fitting, or the inner diameter is checked with an inner diameter plug gauge before the nominal height is sampled. For the convenience of checking the inner diameter, the seat ring is placed below and the shaft ring is placed above. If the inner diameter of the seat ring has obvious quenching and heating oxidation color or does not go through grinding, it is unnecessary to check the inner diameter size. The difference between the shaft ring and the seat ring can be clearly seen, and it is not easy to mix the sleeves. After the thrust ball bearing is assembled, the nominal height T shall be measured to confirm whether it is qualified. During measurement, calibrate with a height block or standard piece, and measure the load. The bearing needs to be rotated dozens of times to reach the minimum height.