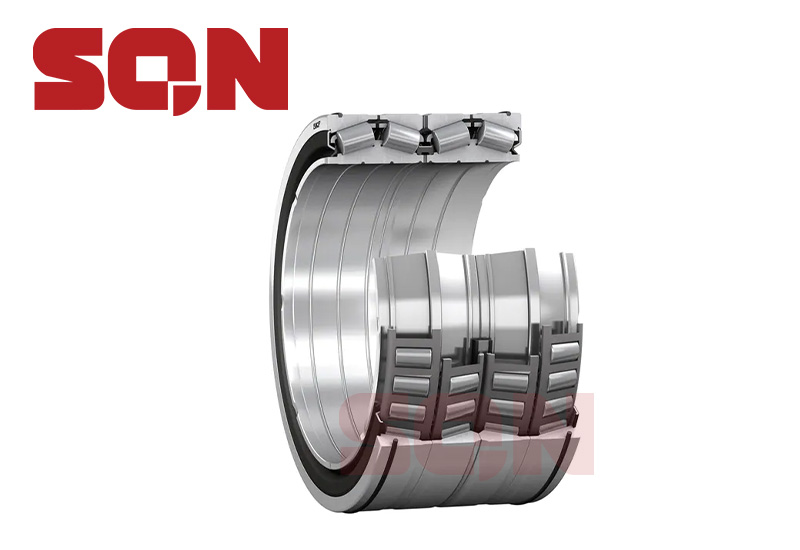

The four-row tapered roller bearing can adapt to the combined (radial and axial) load of low speed and medium speed. They are almost exclusively used in roll applications, such as rolling mills.

Features and advantages

Depending on its design, four-row tapered roller bearings provide the following main features and advantages:

Long service life

The four-cup design (four independent outer rings) provides the best load distribution on all four rows of rollers.

Improve operation reliability

The optimized surface treatment of the contact surface between roller and raceway is conducive to the formation of hydrodynamic lubrication film.

Improved wear resistance

In particular, the bearing is made of extremely clean and uniform steel, and its wear resistance is improved after special heat treatment.

Improved sealing performance, less leakage and less friction heat

The optimized seal design can well ensure the prevention of external pollution, while keeping the friction and friction heat at a low level. The seal design can also better retain lubricants, minimize the impact on the environment and reduce maintenance costs.

The bearing capacity of sealed bearing and open bearing is the same

The optimized and compact seal design can achieve the same internal design.

Complete interchangeability of bearings

Bearings with and without spacer ring, as well as open and sealed bearings can be provided with the same external size. This allows the current standard design bearings to have complete interchangeability with bearings without spacers and/or optimized seal designs.

Detachable installation and simpler inspection

The optimized design without spacer makes it possible to disassemble and separate the roller and cage components and seals. This facilitates installation, disassembly, and maintenance inspection procedures.

Cost-effective solution to save space for journal

The journal can be relatively short, without the need for separate axial bearings, and bearing seats of the same design can be used on both sides of the roll.

The axial positioning on the journal is simpler

A more stringent tolerance on the width of the inner ring helps to determine the tolerance and size of the surrounding components.

Jinfei Liu

Jinfei Liu  +86 18363533331

+86 18363533331  A10, Floor 7, No. 6, Jiefang West Road, Liangxi District, Wuxi City

A10, Floor 7, No. 6, Jiefang West Road, Liangxi District, Wuxi City