Bearing fault solution and clear countermeasures

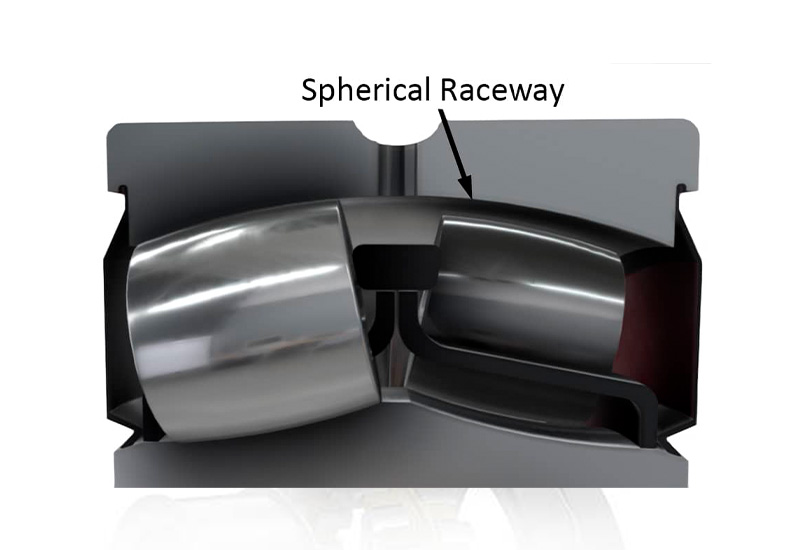

Failure solution: Disassemble and change the front bearing and lubricating oil, adjust the bearing gap, 0.003 mm of the bearing diameter, 0.002 mm axial gaps; make a simple research tool, hand -made the bearing internal cone holes accurately positioning, use the color painting color Methods to check to ensure that the total area of the knife handle and bearing reassured cone holes exceeds 85 %; the butterfly -shaped spring is disassembled and replaced. The completed bearing reinforcement bearing box is used to check the axial tremor with a thousand feet. The near -end end is less than 0.006 mm, and the far side of 150mm is lower than 0.010mm. During the production and processing process, the bearing and noise were normal, and the processing accuracy was determined by the production process, and the fault was excluded.

① Enhance the air compression sperm filtration and drying device, the filter device should drain the pipeline on time, clean or replace the filter element on time;

② Check the cleansing and cooperation of the bearing cone holes and handles anytime, anywhere, and check whether it is normal in the work of the air dryer;

③ Scientific arrangement of manufacturing technology to prevent the reduction rate of raw materials from changing;

④ Forbidden overload operations, if there are faults, the obstacles should be reported immediately. Do not operate with faults.

Jinfei Liu

Jinfei Liu  +86 18363533331

+86 18363533331  A10, Floor 7, No. 6, Jiefang West Road, Liangxi District, Wuxi City

A10, Floor 7, No. 6, Jiefang West Road, Liangxi District, Wuxi City